Alchemy3d

TreeD PC PBT GF 750g Dark Grey

TreeD PC PBT GF 750g Dark Grey

Couldn't load pickup availability

TreeD PC PBT GF

PC PBT GF is a high performance 3d printing filament consisting of 2 polymers in a mix. Polycarbonate is extremely impact, temperature and chemical resistant but comes with the downside of very strong warping. PBT is very temperature and chemical resistant and has very low warping. Together they create a very stiff and strong material that has a great resistance to most environmental effects and has a decently low warping.

The addition of glass fibers adds another vector that reduces warping and increases the strength of this material resulting in a very strong and fairly easy to print material.

It might not be the "geilste" Filament, but it sure is one of the best we've tested so far!

What to expect of this?

- Very high strength, impact and chemical resistance

- Extremely high glass transition temperature, suitable for high temp printers!

- Very low warping for a high temp material

- Good UV resistance

- Extremely stiff

- Can be annealed to increase already great properties (not needed!)

- Low shrinkage from annealing (around 0.1% measured)

- 25% glass fiber content

How to print?

- Dry before printing! This is absolutely required!

- Print from dry box if you can or dry before every print!

- Nozzle Temp: 270 - 290°C

- Bed Temp: 90 - 110°C

- Reduce cooling to increase layer bonding

- Increase ambient temperature to increase layer bonding

- Can be printed open (not recommended tho)

- Anneal at 90°C for 4h to increase strength

- We recommend 0.6 nozzles. Users had no issues with 0.4, but to be safe we don't recommend it.

You might want to join our Discord server (Click me) and have a look at the #pc-pbt-gf channel over there for some more community information and experiences!

Safety instructions

- PC like most plastics should NEVER be burnt. Burning PC releases toxic cancerous fumes!

- 3d printing with plastic generally releases fumes, use in well ventilated areas!

- Keep away from children

- Might be hard to chew - don't try

- Very abrasive!

- Use gloves when handling materials with fiber content!

- Be careful not to inhale any dust from sanding!

Disclaimer

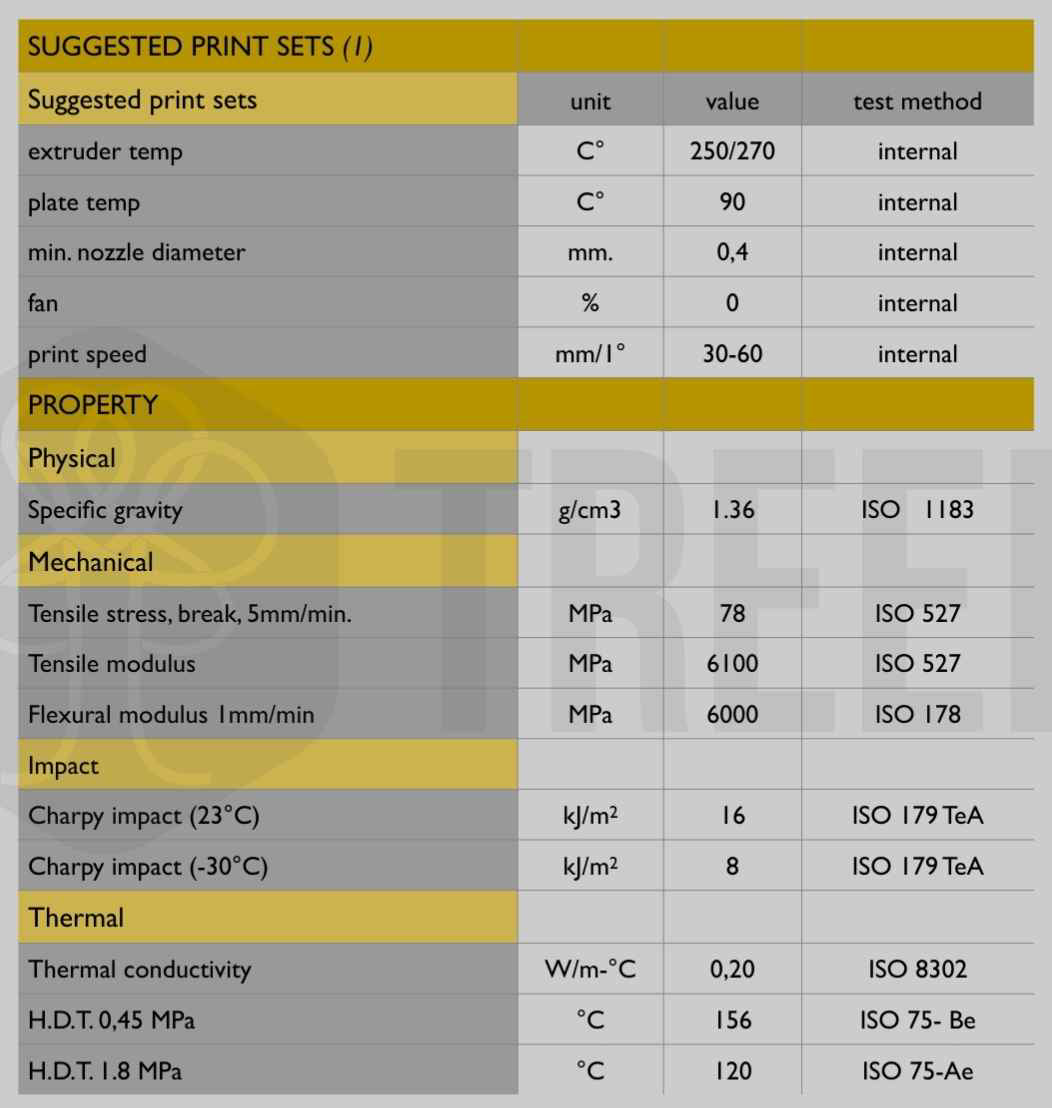

The spec sheet is provided by the manufacturer, we cannot test according to the given standards and need to trust their expertise. If you find discrepancies, please get in touch!

Specs are for annealed parts.

Product safety information (GSPR):

Productidentifier: TreeD PC PBT GF Dark Grey

Manufacturer: TreeD Filaments

Manufacturer Contact: team@treedfilaments.com

Share